Page 32 - 2024 - Q2 - Minerva in Focus

P. 32

MINERVA IN FOCUS Stay Safe

Case Study:

Engine Room Fire

aboard Containership

(The incident occurred on a

vessel of another company)

CO system to extinguish the fire was such that

2

a specialised marine firefighter concluded it “was

just textbook perfect”. Under guidance and with

assistance from the marine firefighting team, the

crew slowly began naturally ventilating the space

by opening vents and hatches to clear the volatile

organic compounds. By the next morning, the

engine room was deemed safe for entry.

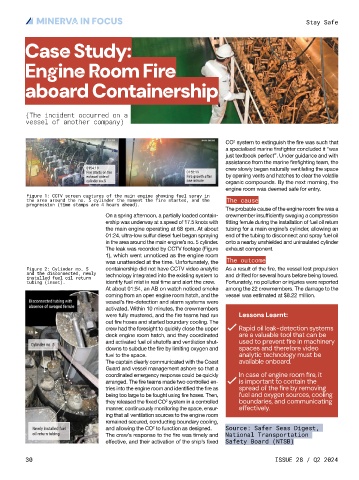

Figure 1: CCTV screen captures of the main engine showing fuel spray in

the area around the no. 5 cylinder the moment the fire started, and the The cause

progression (time stamps are 4 hours ahead).

The probable cause of the engine room fire was a

On a spring afternoon, a partially loaded contain- crewmember insufficiently swaging a compression

ership was underway at a speed of 17.5 knots with fitting ferrule during the installation of fuel oil return

the main engine operating at 68 rpm. At about tubing for a main engine’s cylinder, allowing an

01:24, ultra-low sulfur diesel fuel began spraying end of the tubing to disconnect and spray fuel oil

in the area around the main engine’s no. 5 cylinder. onto a nearby unshielded and uninsulated cylinder

The leak was recorded by CCTV footage (Figure exhaust component.

1), which went unnoticed as the engine room

was unattended at the time. Unfortunately, the The outcome

Figure 2: Cylinder no. 5 containership did not have CCTV video analytic As a result of the fire, the vessel lost propulsion

and the disconnected, newly

installed fuel oil return technology integrated into the existing system to and drifted for several hours before being towed.

tubing (inset). identify fuel mist in real time and alert the crew. Fortunately, no pollution or injuries were reported

At about 01:54, an AB on watch noticed smoke among the 22 crewmembers. The damage to the

coming from an open engine room hatch, and the vessel was estimated at $8.22 million.

vessel’s fire-detection and alarm systems were

activated. Within 10 minutes, the crewmembers

were fully mustered, and the fire teams had run Lessons Learnt:

out fire hoses and started boundary cooling. The

crew had the foresight to quickly close the upper Rapid oil leak-detection systems

deck engine room hatch, and they coordinated are a valuable tool that can be

and activated fuel oil shutoffs and ventilation shut- used to prevent fire in machinery

downs to subdue the fire by limiting oxygen and spaces and therefore video

fuel to the space. analytic technology must be

The captain clearly communicated with the Coast available onboard.

Guard and vessel management ashore so that a

coordinated emergency response could be quickly In case of engine room fire, it

arranged. The fire teams made two controlled en- is important to contain the

tries into the engine room and identified the fire as spread of the fire by removing

being too large to be fought using fire hoses. Then, fuel and oxygen sources, cooling

they released the fixed CO system in a controlled boundaries, and communicating

2

manner, continuously monitoring the space, ensur- effectively.

ing that all ventilation sources to the engine room

remained secured, conducting boundary cooling,

2

and allowing the CO to function as designed. Source: Safer Seas Digest,

The crew’s response to the fire was timely and National Transportation

effective, and their activation of the ship’s fixed Safety Board (NTSB)

30 ISSUE 28 / Q2 2024